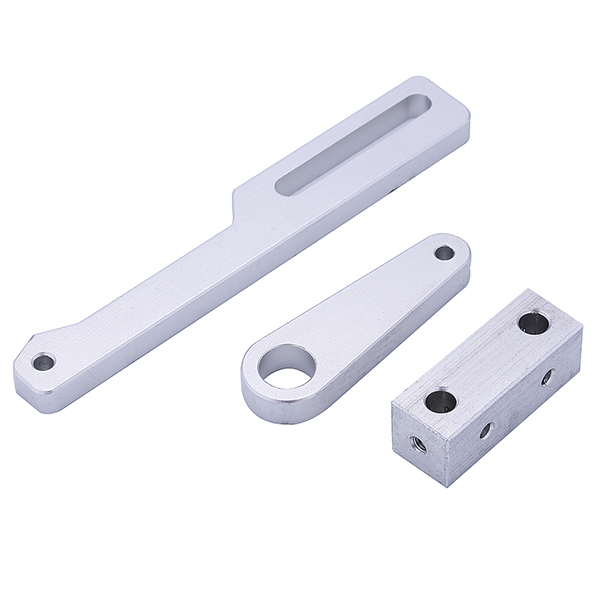

2022 Good Quality milling machine parts - OEM CNC Metal/Stainless Steel Machining/Turning/Milling Part – KGL

2022 Good Quality milling machine parts - OEM CNC Metal/Stainless Steel Machining/Turning/Milling Part – KGL Detail:

Processing equipment: CNC Milling machine

Processing method: Rough Milling,Finish Milling,Punching,Tapping,Surface treatment.

Heat treatment:Thermal Refining,Normalizing,Quenching etc.

Surface treatment:Polishing,PVD/CVD coating,Galvanized,Electroplating,spraying,Anodize treatment ,sandblasting, painting and other chemical handings

Application:Car, medical, carrrier,ship,excavator, Automation machine,medical device, industrial machine,automobile, and electric appliance etc.

Drawing format: PRO/E,CAD,Solid works,IGS,UG,CAM,CAE,PDF.

Service:According to customer requirements, provides production design,production and technical service,mold development,and processing to offer one-stop service.

Delivery time:7-30 days

MOQ:Negotiable

Quality control:100% full inspection for small QTY, ISO sampling inspection for mass productions.

Features

Customized requirements for automobile trial production

Various processing and surface treatment processes involving metal and plastic parts meet the different needs of automobile trial production and parts manufacturing, including CNC parts processing, rapid injection molding, sheet metal, painting, oxidation, powder spraying, electroplating, etc.

Flexible and efficient production process management

Implement lean production, professional project management and engineering team with technical expertise, from design optimization suggestions to production process improvement, achieve high efficiency and high quality, and continuously improve customer satisfaction.

From CNC handboard processing to small batch customization

From 1 piece to 10000 pieces, we provide a variety of parts processing solutions to meet your exact specifications. When you need to deliver custom parts in a short time, we can provide engineering support without any restrictions.

Find the advantages of customized CNC machining for your parts

01. Optimized DFM recommendations

Design problems can be found in advance without waiting for production. Our engineers will provide cost-effective and reasonable suggestions from the aspects of design, materials, process and manufacturability.

02. Advanced processing technology

We are equipped with advanced 3-axis, 4-axis and 5-axis CNC machining equipment, which can provide different types of precision CNC machining, including milling and turning, as well as auxiliary EDM and WEDM.

03. One stop post-processing

We not only provide complete post-treatment processes internally, including grinding, polishing, sandblasting, painting, printing, etc., but also provide various special surface treatment options such as oxidation, powder spraying, electroplating and so on in combination with external resources.

04. ISO9001 certified factory

We are committed to continuously improving and optimizing the quality control process. The professionally trained quality inspection team has advanced testing instruments such as CMM and 3D scanner, which can ensure that your project meets strict quality specifications.

Our Service

Fast communication, Professional technology, Excellent product quality, Reasonable Price and Wonderful after-sale service.

Packing

Bubble wrap/pearl wool + Carton or Pallet; As per customized specifications

Lead Time

1.Samples delivery:5-7 working days

2.Orders delivery:15-20 working days

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to provide you with excellent service of processing for 2022 Good Quality milling machine parts - OEM CNC Metal/Stainless Steel Machining/Turning/Milling Part – KGL , The product will supply to all over the world, such as: Czech, Georgia, Mombasa, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we've gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.